Hyundai Elantra (CN7): Engine Mechanical System / Drive Belt System

Drive Belt

Repair procedures

* There are two methods to when removing the drive belt.

[When removing the drive belt from the top of the vehicle]

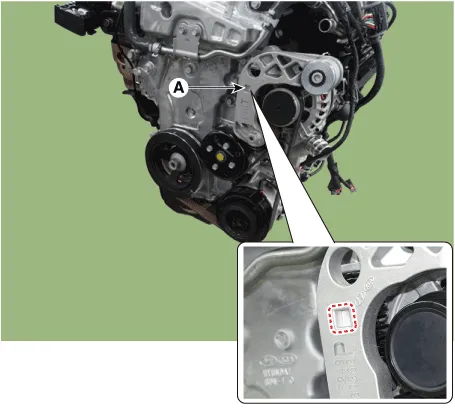

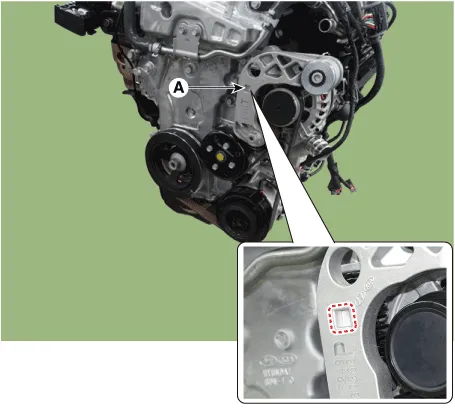

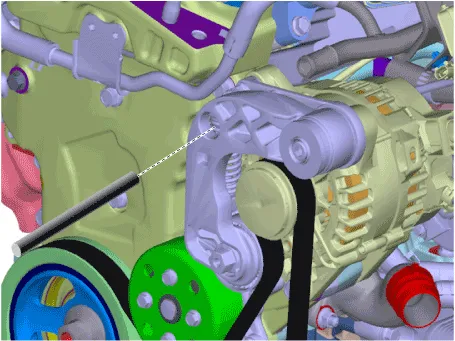

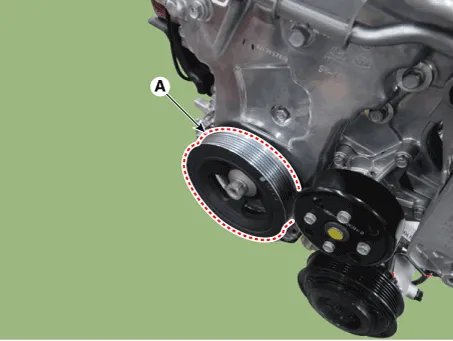

| 1. | Install the wrench to the drive belt tensioner repair hole (A) and turn it clockwise.

| •

| Fix the drive belt tensioner by installing fixing pin after turning the drive belt tensioner to clockwise.

|

| •

| Use fixing pins that have the same outer diameter as a 6mm(0.2362 in.) hex wrench or a 6mm(0.2362 in.) hex wrench. |

|

|

| 2. | Remove the drive belt (A).

| •

| When removing the drive belt, remove the drive belt from the water pump pulley. |

|

|

| 3. | Install in the reverse order of removal. | •

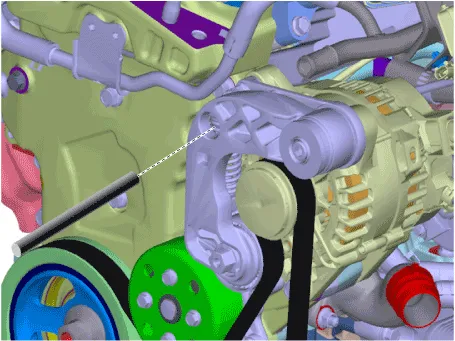

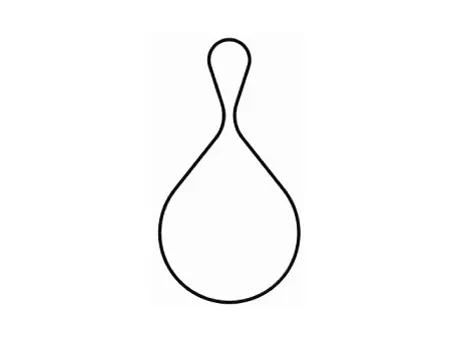

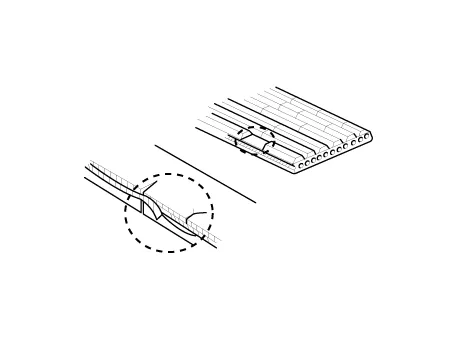

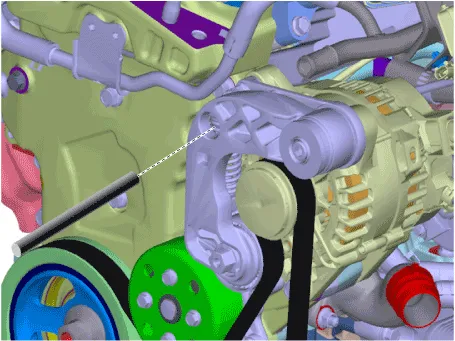

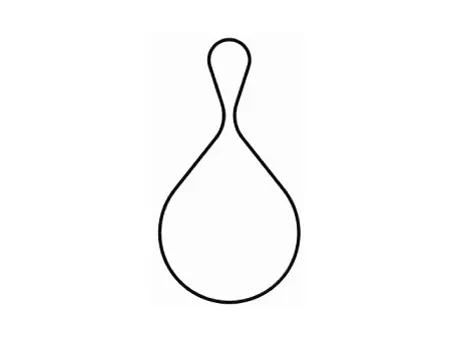

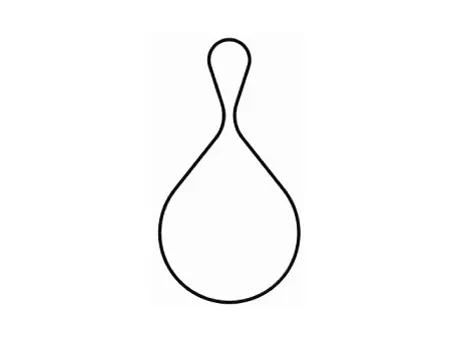

| When installation of drive belt, make the drive belt as a round hook shape bigger than alternater pulley as a picture down below. Then install it with following order of alternator → airconditioner compressor → crankshaft damper pulley → water pump → drive belt tensioner.

|

|

|

[When removing the drive belt from the bottom of the vehicle]

| 1. | Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

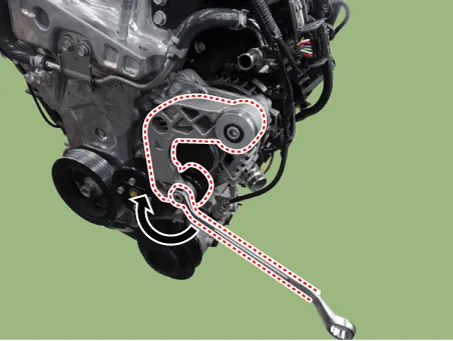

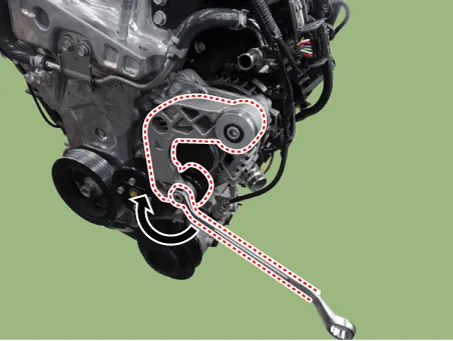

| 2. | Turn the spanner to clockwise after installing it to drive belt tensioner arm boss.

| •

| Fix the drive belt tensioner by installing fixing pin after turning the drive belt tensioner to clockwise.

|

| •

| Use fixing pins that have the same outer diameter as a 6mm(0.2362 in.) hex wrench or a 6mm(0.2362 in.) hex wrench. |

|

|

| 3. | Remove the drive belt (A).

| •

| When removing the drive belt, remove the drive belt from the water pump pulley. |

|

|

| 4. | Install in the reverse order of removal. | •

| When installation of drive belt, make the drive belt as a round hook shape bigger than alternater pulley as a picture down below. Then install it with following order of alternator → airconditioner compressor → crankshaft damper pulley → water pump → drive belt tensioner.

|

|

|

Drive Belt Inspection

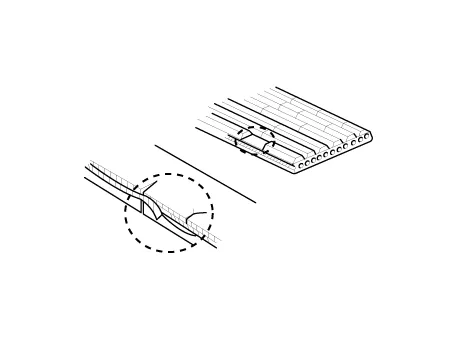

| 1. | Visually check the belt for excessive wear, frayed cords etc.If any defect has been found, replace the drive belt. | •

| Cracks on the rib side of a belt are considered acceptable. If the belt has chunks missing from the ribs, it should be replaced. |

|

|

Drive Belt Tensioner

Repair procedures

| 1. | Remove the drive belt. (Refer to Drive Belt System - "Drive Belt") |

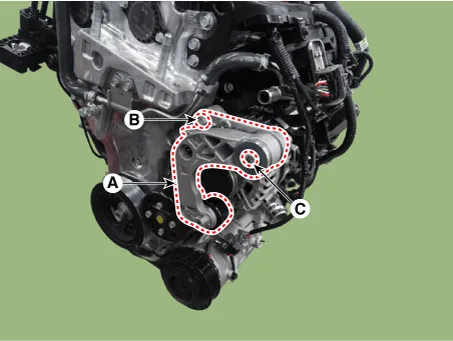

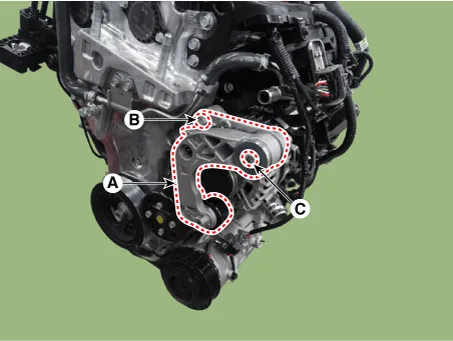

| 2. | Remove the drive belt tensioner (A). Tightening torque Bolt (B) : 18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.4 lb-ft) Bolt (C) : 34.3 - 41.2 N.m (3.5 - 4.2 kgf.m, 25.3 - 30.4 lb-ft) |

|

| 3. | Install in the reverse order of removal. | •

| Check the belt tensioner for crack, and damage. Replace if necessary. |

|

|

Check the drive belt tensioner for excessive foreign substances, crack, damage or sticking of pivot shaft. Replace if necessary.

Crankshaft Damper Pulley

Repair procedures

| 1. | Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 2. | Remove the drive belt. (Refer to Drive Belt System - "Drive Belt") |

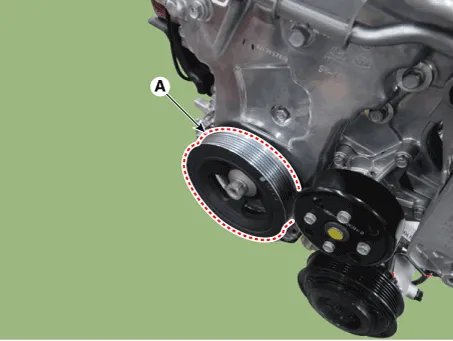

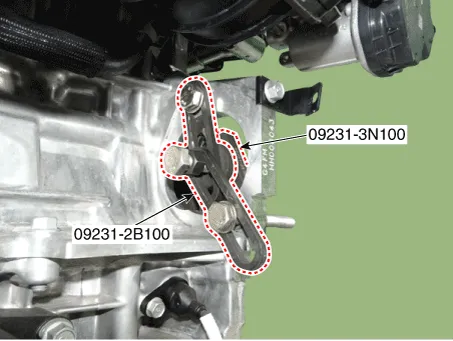

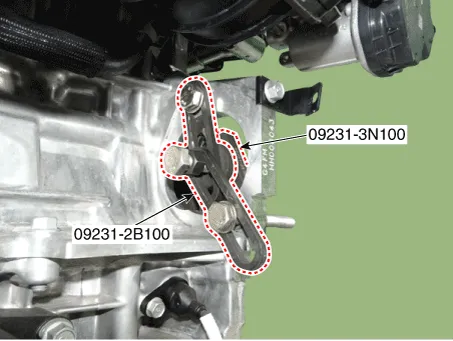

| 3. | Remove the crankshaft damper pulley (A). Tightening torque : 66.7 - 70.6 N.m + 98 - 102°[6.8 - 7.2 kgf.m + 98 - 102°, 49.2 - 52.1 lb-ft + 98 - 102°] |

| •

| Fix the ring gears using the SST(09231-2B100,09231-3N100) after removing thestarter. Then remove the crankshaft damperpulley.

|

|

|

| 4. | Install in the reverse order of removal. |

Check the crankshaft damper pulley for vibration in rotation, oil or dust deposit of V-ribbed part. Replace if necessary.

Repair procedures

Removal

•

Use fender covers to avoid damaging painted surfaces.•

To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

Other information:

Instructions (R-134a)When Handling Refrigerant1.R-134a liquid refrigerant is highly volatile. A drop on the skin of your hand could result in localized frostbite. When handling the refrigerant, be sure to wear gloves. 2.It is standard practice to wear goggles or glasses to protect your eyes, and gloves to protect your hands.

Repair procedures

Replacement1.Disconnect the negative (-) battery terminal. 2.Remove the heater and blower assembly.(Refer to Heater - "Heater Unit") 3.Remove the heater core cover (A) after loosening the mounting screws.4.Pull out the heater core (A) from the heater unit.