Hyundai Elantra (CN7): Engine Control System / Electric WGT Control Actuator

Description and operation

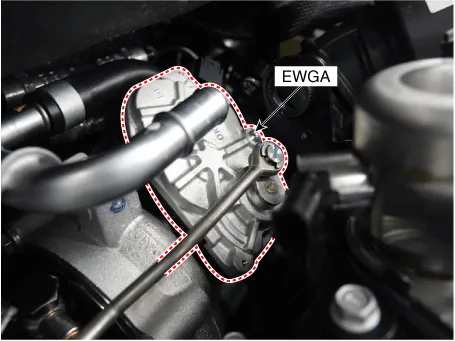

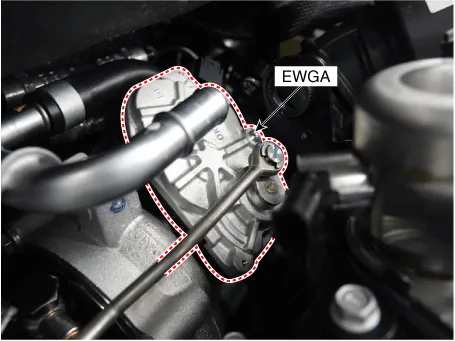

The Electric Waste Gate Actuator(EWGA) is installed on the turbocharger. EWGA operates vain in west gate turbocharger and controls the compressed air by PWM signal of ECM.

Specifications

EWGA Position Sensor [integrated into EWGA]

Position

|

Output Voltage [V]

|

Operating Angle [°]

|

Range [mm]

|

Mechanical Closed Position

| 4.8

| 1

| 0

|

Electrical Closed Position

| 4.2

| 12

| 1.8

|

Electrical Open Position

| 1

| 79

| 16

|

Mechanical Open Position

| 0.5

| 90

| 19

|

EWGA DC Motor [integrated into EWGA]

Item

|

Specification

|

Coil Resistance (Ω)

| 28.3 - 31.1 [20°C (68°F)]

|

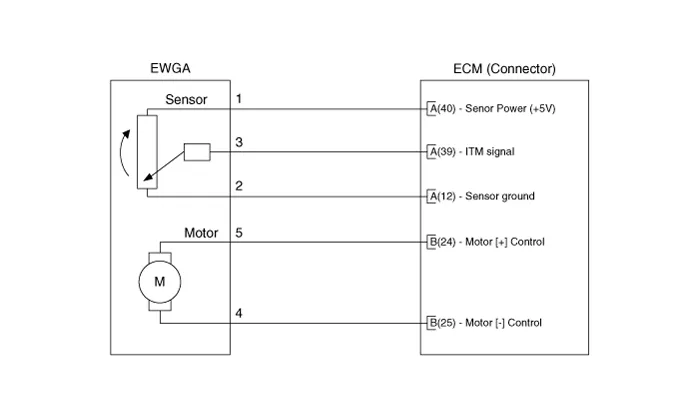

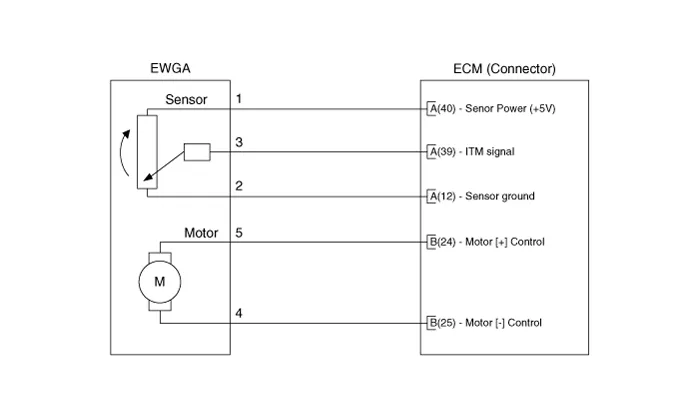

Schematic diagrams

Harness Connector

Repair procedures

| 1. | Turn the ignition switch OFF and disconnect the battery negative (-) cable. |

| 2. | Remove the air cleaner assembly. (Refer to Engine Mechanical System - "Air Cleaner") |

| 3. | Remove the intercooner inlet pipe. (Refer to Engine Mechanical System - "Intercooler") |

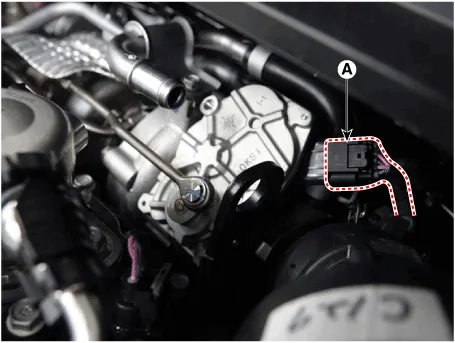

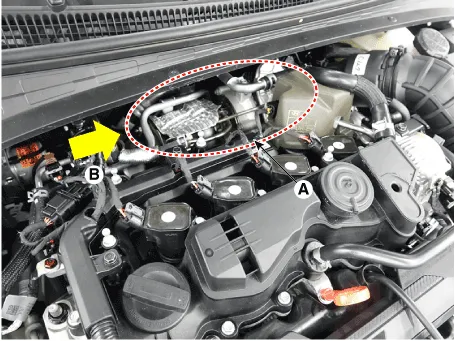

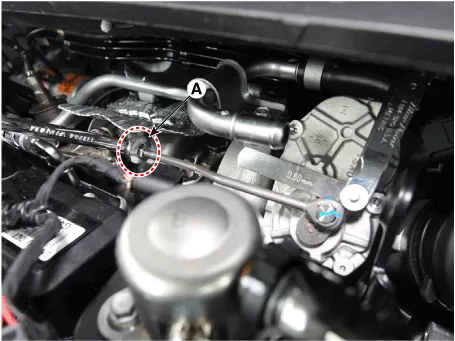

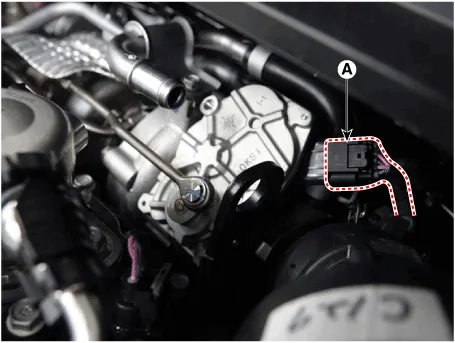

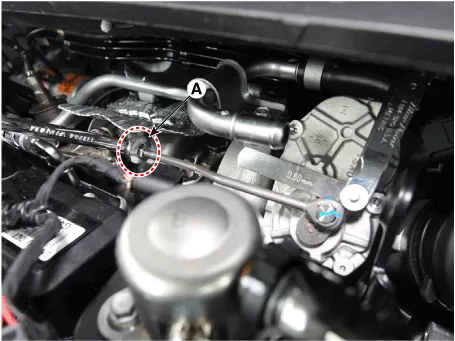

| 4. | Disconnect the EWGA connector (A).

|

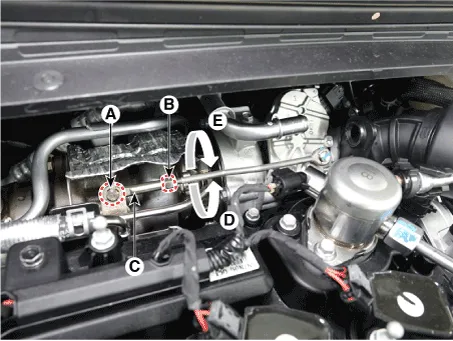

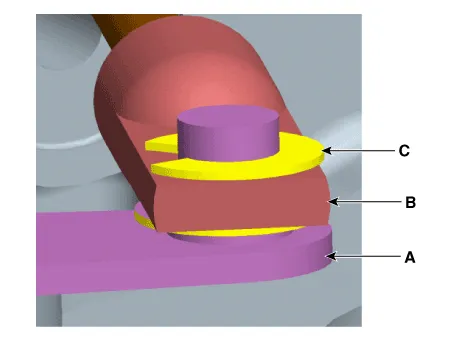

| 5. | Remove the shaft link assembly (B) after removing the C-ring (A).

|

| 6. | Remove the EWGA after removing the bolts (A). Tightening Torque : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft) |

|

| •

| When replacing the Electric WGT Control Actuator, perform the rod adjustment procedure. |

| •

| When install the electric WGT control actuator, do not reuse a C-Ring. |

|

| 1. | Install in the reverse order of removal. |

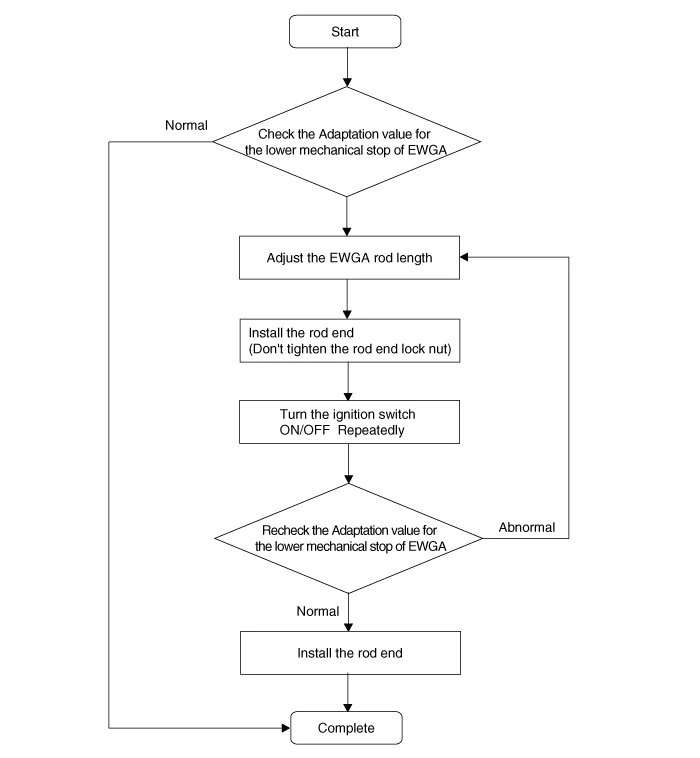

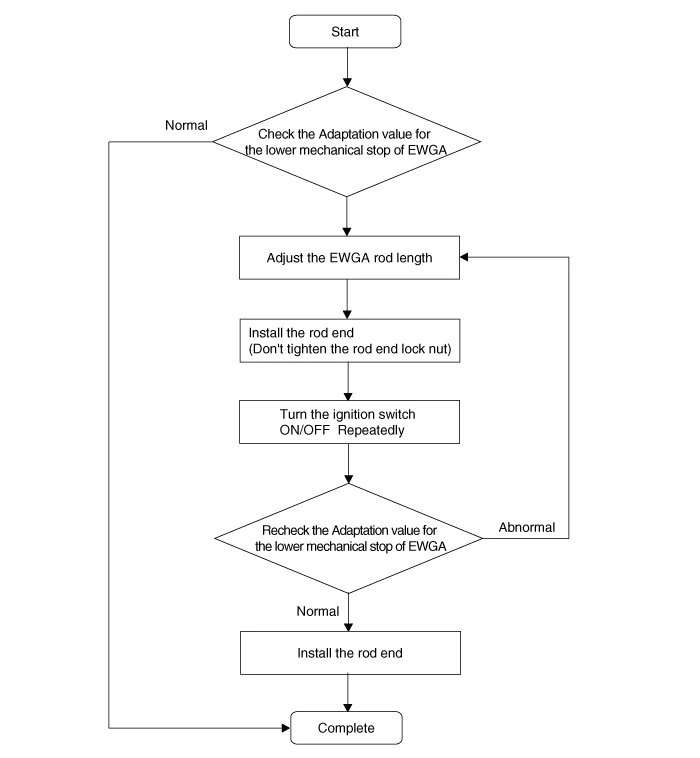

[Rod Adjustment Procedure Flowchart]

| 1. | Check that the waste gate turbo charger is coolenough to work. | •

| Use an electric fan to cool down fast. |

| •

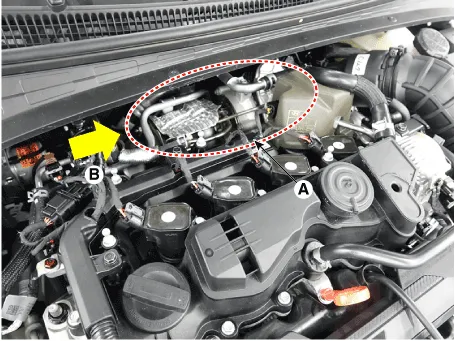

| The cooling part (A) and the wind direction (B) areas follows.

|

|

|

| 2. | Turn the ignition switch to OFF position. |

| 3. | Connect the diagnostic tool to DLC connector (16pin) under the driver side instrument panel. |

| 4. | Turn the ignition switch ON. | •

| Do not start the engine. |

|

|

| 5. | Select VIN or Vehicle on the initial screen. |

| 6. | Enter "Engine Control" menu after slelecting vehicleinformation (Vehicle model, Model year, Engine type)or entering the VIN number. |

| 7. | Select the "Current Data". |

| 8. | Without starting the engine, repeatedly turn theignition ON for 5 seconds and OFF for 5 seconds,and then check the "Adaptation value for lowmechanical stop of EWGA" on the diagnostic tool. Repeat this step until the amount of difference in theadaptation value from the previous cycle is below 0.05V. | •

| Do not start the engine. This is a crucial step toread the correct adaptation value. |

|

|

| 9. | Check that "Adaptation value for the lower mechanical stop of EWGA" is within the specified voltage value. |

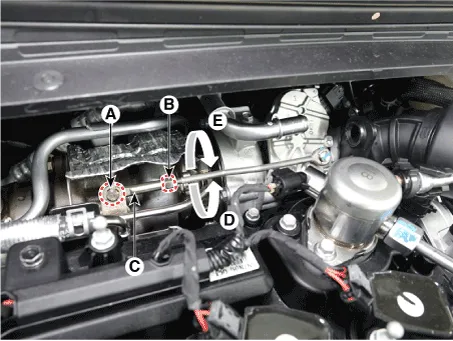

| 10. | If the measured voltage value is not within the specified voltage value, adjust the EWGA rodlength. Otherwise, no further procedure is required. | (1) | Loosen the rod end lock nut (B) and remove the C-ring (A). |

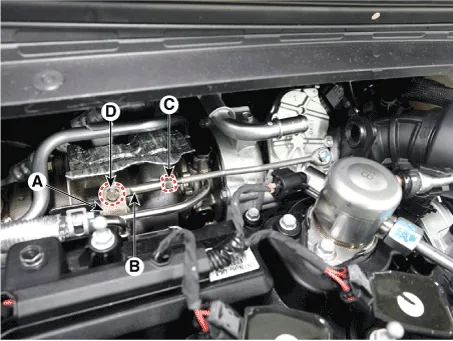

| (2) | Adjust the rod end part (C) by rotating it clockwise (D) or counterclockwise (E) to satisfy the specification.

Adaptation valuefor the lower mechancalstop of EWGA (V)

| Adjusting directionof rod end

| Rod length variation(After adjustment)

| > 3.7V

| counterclockwise

| Longer

| < 3.5V

| clockwise

| Shorter

|

Turning angle

| Changing level of the adaptationvalue (V)

| 0.5 mm (180°)

| Approx. 0.1V

| 1 mm (360°)

| Approx. 0.2V

|

|

|

|

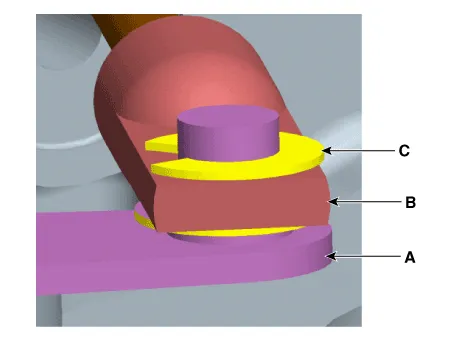

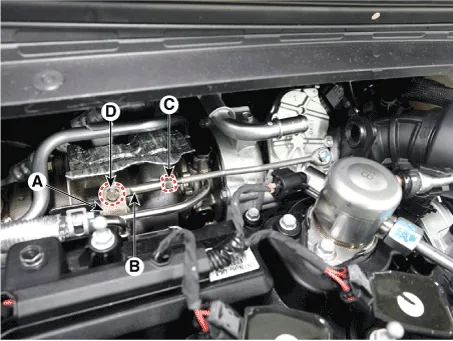

| 11. | Install the rod end (B) to the turbocharger lever (A) temporarily. Do not tighten the rod end lock nut (C) and C-ring (D).

|

| 12. | Check the "Adaptation value for the lower mechanical stop of EWGA" after selecting "Current Data" menu. Turn the ignition switch ON/OFF repeatedly until the changing value of the "Adaptation value for the lower mechanical stop of EWGA" is within 0.05V. | •

| Turn the ignition switch ON/OFF. But hold 5 seconds at each IG ON or OFF state. |

|

|

| 13. | If the measured voltage value is not within the specified voltage value, repeat procedures 9 - 12 until the voltage value is within the specified voltage value. |

| 14. | If it is within the specified voltage value, install the rod end to the turbocharger lever. | (1) | Install the rod end (B) to the turbocharger lever (A) temporarily. |

| (2) | Fix the C-ring (C).

|

|

| 15. | Install the 0.6mm filler gauge between EWGA lever (A) and rod end (B).

|

| 16. | Tighten the lock nut (A).

|

Description and operation

DescriptionInstalled on the high pressure fuel pump, the Fuel Pressure Regulator Valve controls the fuel amount flowing into the injectors in accordance with the ECM signal calculated based on various engine conditions.

Description and operation

DescriptionRCV (Recirculation Valve) Control Solenoid Valve is installed on the intercooler inlet pipe and operates the RCV actuator which controls the by-pass passage of the turbocharger compressor.

Other information:

Description and operation

DescriptionThe auto defogging sensor is installed on front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives a signal from the sensor and restrains moisture and eliminates defog by the intake actuator, A/C, auto defogging actua

Trouble Symptom ChartsTrouble Symptom 1Trouble Symptom 2

Trouble symptom

Probable cause

Remedy

The set vehicle speed varies greatly upward or downward"Surging" (repeated alternating acceleration and deceleration) occurs after settingMalfunction of the vehicle speed se